ProfloorTM 3000

short Describe the products

- Description

Description

ProfloorTM 3000 Concrete floor polishing system with high gloss finish :-

Uses The ProfloorTM 3000 service provides an extremely hard, abrasion resistant, high gloss, smooth, durable, and easy to maintain floor surfaces. ProfloorTM 3000 is ideally suited for all industrial areas subjected to the heaviest traffic, e.g. power stations, heavy industry, warehouses, loading bays andworkshops.

Advantages :-

Great aesthetics: No stains from tire marks and oils. High resistance to wear, abrasion, heat, and dusting.

Available in many colors and stains.

Enhanced working environments: Sound absorbing. Flat surface decreases the vibrations that appear in forklifts. Reduces stress on electronic components caused by electrostatic discharge.

Economical: Permanent high gloss, long lasting, nothing to peal out and requires no re-painting.

Ecological: Materials and methods are harmless to the environment. The cleaning needs soap and water harmless to the environment.

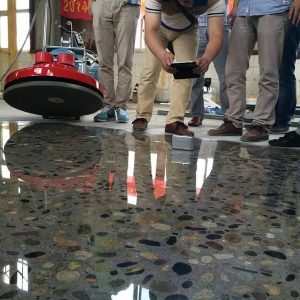

The ProfloorTM 3000 All floor covering materials, old floor coatings, oil, grease and concrete laitance shall be removed. Diamond grinding shall continue to achieve calibrated, even floor level. Impregnating concrete hardener is then applied. Once the hardener has densified the surface, polishing steps are performed.

The Result is an incredibly rich, lustrous shine. The floor will actually reflect not only the lighting in the facility, but will also mirror the colors from the objects surrounding it.

PROFLOOR™ Concrete Floor Polishing System Click Here